Reliable and secure storage and data delivery are crucial issues for industries which are increasingly focused on the Industrial Internet of Things (IIoT).

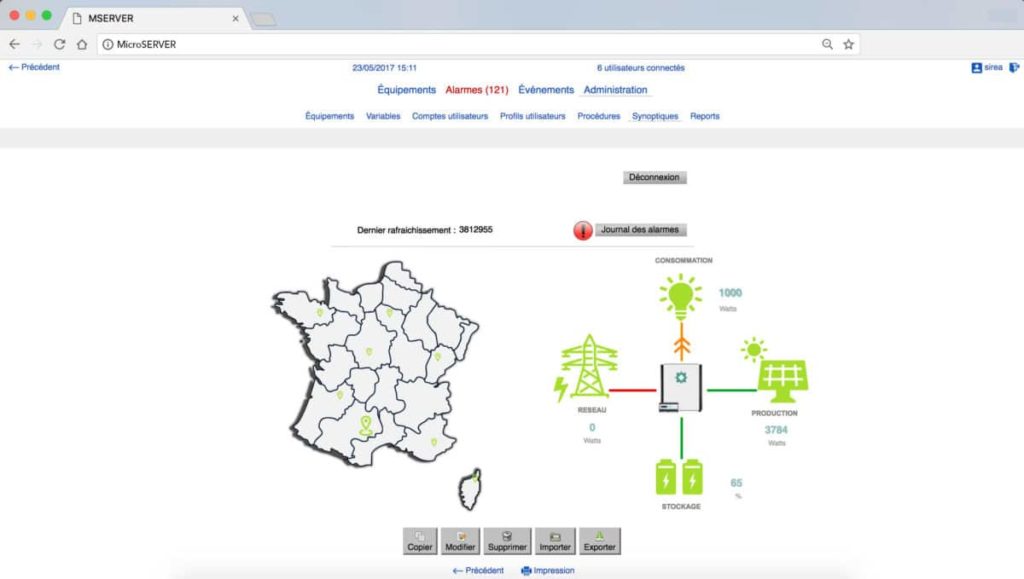

With that in mind, our IIoT platform MicroSERVER, which enables users to store and analyse data in real time, has just exceeded 15,000 controller connections, collecting data from thousands of smart devices.

An exponential figure

Since its creation in 2010, the platform has continued to develop to accommodate an increasing number of different technologies and to provide greater flexibility to our clients. Today it’s compatible with the Modbus, ModbusTCP, Profinet, SNMP, LoRa and Sigfox protocols and 20,000 smart data sources could be connected by the end of this year.

Enhanced performance

MicroSERVER was created in an environment adapted to the world of industry. It provides users with essential functions to apply the concepts of industry 4.0.

The platform can provide users with a visual representation of the data through graphics (curves, bar graphs and animated flow charts) or through tables of values (events, alerts, status lists) to give more meaning and so that data is interpreted correctly before appropriate action is implemented.

The best way to implement this action is to do so directly, using the same intuitive and easy-to-use interface – which is where MicroSERVER comes in. It makes it possible to control your smart industrial controllers through two-way communication, interacting remotely with the equipment.

MicroSERVER in practice

With thousands of connections within the industrial sector to acquire, aggregate and use the consumption data of production tools in factories, MicroSERVER is also commonly used in the health sector. It is often used to manage medical data and to report alerts. Also popular within the energy sector, it can be used to supervise electric power generation plants to improve maintenance operations.